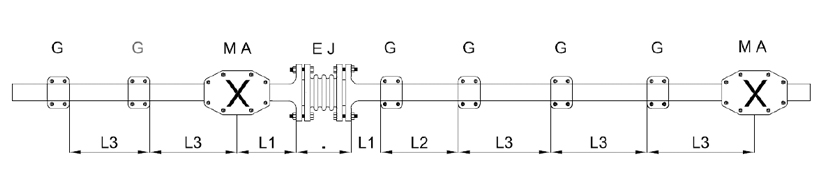

Are points which seperateand isolate expansion sections constituted on the pipe system. In simple words, they are junction points which carry the emerging loads on the pipe section. It can be made in various forms but location is very important related to the operation of the expansion joint. ; Long piping systems are divided into shorter expanding sections, and isolated by main anchors. Thus the movements in the individual expanding sections are absorbed by the axial expansion joints in this section.

MA = MAIN ANCHOR

G = PIPE GUIDE

EJ = EXPANSION JOINT

MA ( Fixed Point-Main anchor )

G ( Sliding Support-Guide )

L1 =4 .D

L2 =14 .D D = Diameter

L3 =See Thermal Expansion Table

FMA=Fi+Fy+Fs+Fd (kg)

FMA=Load of fi xed point

Fi=Load arrising from internal pressure

Fi=Pw . A Pw=Working Pressure (kg/mm2)

A=Pipe ınternal Cross Section Area (mm2)

Fy=Force arrising from bellow swing

Fy=Cy Δx/2

C=Bellow Axial Springrate (kg/mm)

X=Max Movement Amount (mm)

Fs= Sliding Support Friction Load

Fs=M.G.L

M=Friction Coeffi cient

G=Pipe Total Weight (kg/m)

L=Pipe Lenght(m)

Fd=Centrifugal If the fi xed in on the elbow

Fd= (2A.φ.V2)/g sin θ/2

A=Pipe Internal Cross section Area (m²)

φ=Density of Fluid (kg/m³)

V=Flow Velocity (m/sec)

g=Gravity Acceleration (m/sec²)

θ=Elbow Angle

Axial expansion joints are not provided with attachments to restrain pressure thrust, such as limit rods or hinges. Therefore the over-extension and distortion of expansion joints can be prevented by alignment guides under all kinds of operating conditions in a correctly designed piping system. They allow the axial movement of the pipes. The Pipe Guide Spacing Chart should be used to determine the distance between guides. For the first guide next to the expansion joint the 4D + 14D principle should be used.

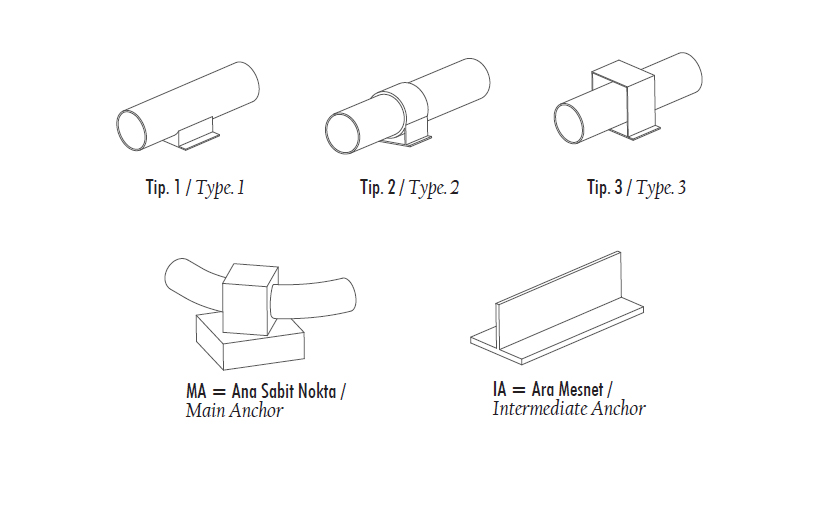

Main Anchors: These types of anchors are the most important ones in the pipeline, because they resist the forces acting upon them.

Intermediate Anchors: Intermediate anchors do not resist the pressure thrust. However this type of anchors withstands spring resistance of the bellows as well as the frictional forces.

Pipe Guides: Pipe guides provide the proper alignment of the expansion joint movements and prevent the bowing and buckling of the pipeline. Hence they are one of the most important components of the system.