The elastic metal bellowed parts absorbing the heat induced expansion or contraction of pipelines conveying hot or cold fluids or subject to drastic changes in ambient temperatures are called expansion joints. If no measures are taken against changes in size of pipelines, high pressure resulting from expansion or contraction creates problems at connection points and equipment. The most proper and affordable solutions to eliminate those problems are the metal bellow expansion joints designed to compensate different types of size chances, which do not necessitate any maintenance. In brief, assemblies comprising single or multiple bellows used to compensate the change in size and to eliminate the problems caused by it due to the heat induced expansion and contraction in pipelines, ducted air systems and tanks can be called expansion joints.

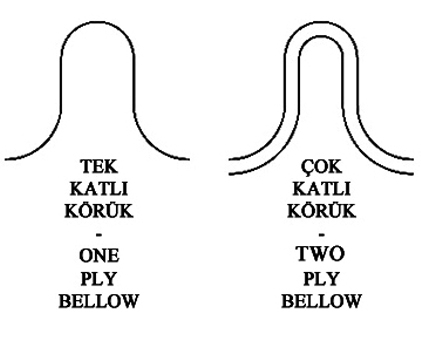

The main components of expansion joints are bellows. Produced of multi-layer stainless-steel they function as springs. Expansion joints should be designed in regard to the working conditions of the systems (temperature, pressure, amount of movement, characteristics of the fl uid, etc.) where expansion joints are needed.

The main components of expansion joints are bellows. Produced of multi-layer stainless-steel they function as springs. Expansion joints should be designed in regard to the working conditions of the systems (temperature, pressure, amount of movement, characteristics of the fluid, etc.) where expansion joints are needed. Thus;

DIMENSION (pipe diameter): The diameter of the expansion joints are determined by the diameter of the pipeline where the expansion joints are to be used. The capabilities of expansion joints to absorb various types of movements (axial, lateral, and angular) are determined by the diameter of expansion joints, their resistance to pressure and temperature values.

FLUID: The fluid to come in contact with the bellows should be specified before the selection of expansion joints. For operating conditions like abrasion, corrosion or high density specifi c materials and specific designsmay be needed. In the same way the materials used to clean the pipe systems have to be compatible with the material of the bellows.

PRESSURE: The most important element in the design of expansion joints is the determination of minimum and maximum values of pressure.

TEMPERATURE: All heat sources as well as their temperature values in the environment of the expansion joints should be taken into account while the working temperatures of the expansion joints are determined.

MOVEMENT: The movements of the expansion joints, induced by temperature changes should be determined. (The methods to calculate those offsets are explained in the “Calculations” section.) Expansion Joints characterized by those criteria mentioned above are designed to compensate three different types of movements. Those movements, influencing the design and type of the expansion joints can be classified under three major groups: Axial, Lateral and Angular movements.

Thus;

Axial Movements: The movements of expansion or contraction parallel to the axis of the bellows are called axial movements.

Lateral Movements: The offset movements vertical to the axis of the bellows are called lateral movements. These movements may also occur along multiple axes.

Angular Movements: The movements resulting from angulations of the expansion joints with respect to their axes are called angular movements.