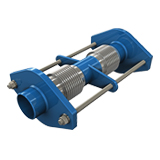

KRS-24 Universal Weldend With Tierods Lateral Expansion Joints are specific expansion joints, consisting of one or more angular expansion joints used to absorb the thermal expansion in a plane vertical to the axis. The potential expansion amount to be absorbed can be augmented by increasing the distance between the bellows. This type of expansion joints may absorb big amounts of expansions. Especially the assemblies consisting of more than one lateral expansion joints are the most effective ones to absorb big amounts of expansions.

Bellow Features

Standard Production : AISI 321 (DIN 1.4541)

Special Production : AISI 304 (DIN 1.4541), AISI 309 (DIN 1.4828), AISI 316 (DIN 1.4401), AISI 316 ti (DIN 1.4571) etc

Design Information :

Design Pressure : 16 BAR

Design Temperature : – 196 + 550 C

Tierod-Nut Features :

Standard Tierod : Rst 37-2 (DIN 1.0038)

On Request Stainless Steel etc.

Standard Nut : Rst 37-2 (DIN 1.0038)

On Request Stainless Steel etc.

Flange-Neck Features :

Standard Flange-Neck : Rst 37-2 (DIN 1.0038)

Special Flange-Neck : Stainless Steel DIN, BS, EN, ANSI etc.

Applications

For absorbing lateral movement, All machines, All pumps, All motors, Industrial applications, Exhaust systems, Gas and water lines, Drinking water lines, etc.

Painting Information

All flanges between DN25-DN500 are with special paint ( for corrossion protection).

Special Note

Design temperature can be designed until + 950 C as well.Products are under our 2 years quarantee for factory faults. For special requirements please consult us. Please see Useful technical tables pages for flange and pipe size tables.Use liner to protect bellow from wear due to abrasive media.

What Is Lateral Movement ?

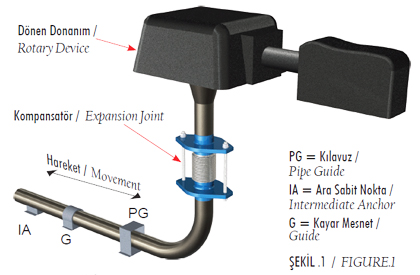

The offset movements vertical to the axis of the bellows are called lateral movements. These movements may also occur along multiple axes. As depicted in the fi gure, pressure thrust is compensated by using limit rods installed at lateral expansion joints and intermediate anchors are used instead of main anchors. A planer pipe guide is used providing the thermal expansion in the vertical pipe leg to be taken as natural flexibility in the horizontal pipe run.