KRS-5 Axial expansion joints are used to absorb the thermal expansion and vibration parallel to the axis of the straight pipelines. Long piping systems are divided into shorter expanding sections, and isolated by main anchors. Thus the movements in the individual expanding sections are absorbed by the KRS-5 axial expansion joints in this section..

Bellow Features

Standard Production : EPDM – Epidiem (Water, Hot water, Cooling water, steam, acid etc.)

Special Production : NBR – Neopren (Oil, Water with salt, gas, naturalgas, fueloil, compressed air systems, antireeze, composite cooling systems etc.)

Design Information :

Design Pressure : 16 BAR

Design Temperature : 110 C max

Burst Pressure : 45 BAR on 25 C

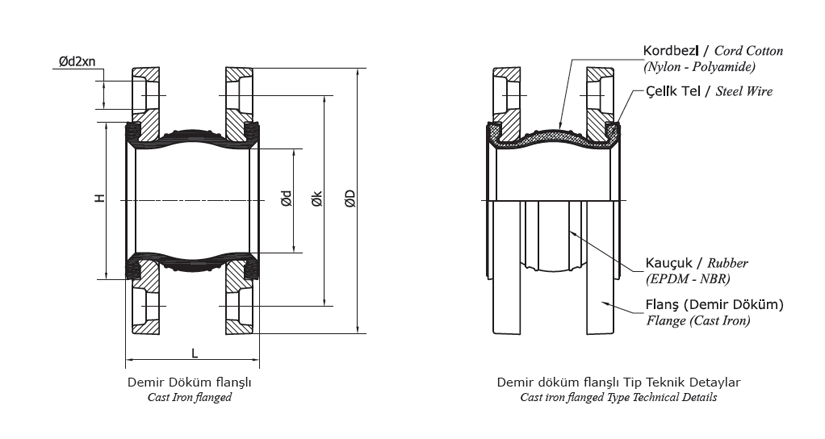

Flange Features :

Standard Flange : Cast Iron (DIN 2501) PN 16

Special Flange : Carbon Steel – Stainless Steel , ISO, BS, VG, SAE, ANSI etc.

Cord Fabric Features :

Standard Cord : Nylon – Polyamide

Applications

For absorbing axial movement, For reducing vibration and noise, All HVAC systems and similiar systems, On air compresors, On pumps, On chemical plants, Industrial applications, Gas and water lines, Drinking water lines, etc.

EPDM :

Good heat resistance and suitable for alkaline waste water, compressed air telpolymer (oil free) and chemicals, weather-resistant, good gastightness except for hydrocarbon

Temperature range: -35°C up to 130 °C

Not suitable for oils or fatty media

NBR :

Oil and fuel quality, also suitable for gasses, solvents and fats. High abrasion resistance

Temperature range: -20 °C up to +90 °C (120°C)

Not suitable for steam or hot water

NEOPRENE :

Water quality, weather resistant, suitable for some small groups of lyes as well as compressed air and lightly oil-related media

Temperature range: -25 °C up to 90 °C

Flange Information

The flanges of between DN 25 – DN 300 are cast-iron. Above DN 300 and over sizes are carbon steel( on request also avaliable carbon steel flanges for small sizes.)

Special Note

Products are under our 2 years quarantee for factory faults. For special requirements please consult us. Please see Useful technical tables pages for thermal expansion tables.For corrosive media, please consult us.

Multifunctional Usage

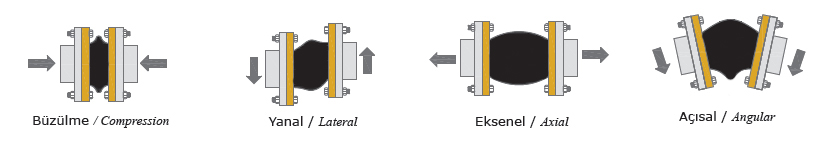

KRS – 5 Rubber Expansion Joints can be used for absorbing axial, lateral and angular movements as well. The Picture on the left side that shows some movements during operating. KRS—5 Rubber Expansion Joints can use for absorbing longditudinal axial movements in pipe lines, lateral movements in high pressure and angular movements in defective pipe guide applications. Durable designed KRS—50 Rubber Expansion Joints which use in succesful applications can solve problems, If the compensators desingn correctly according to purpose of usage.

Advices Before Installation

Figure 1 – The instalation for a compensator absorbing axial movement

Figure 2 – The instalation for a compensator absorbing axial and lateral movement in a seperated piping systems.

Figure 3 – The instalation for a compensator transforming axial movement to angular movement. If the angular movement is big, use 2 pieces of compensators for more comfortable operating systems.

Figure 4 – This kind of instalation has high rates of absorbing movements

Figure 5 – The instalation for an another compensator absorbing axial movement

Figure 6 – Correct Flange Installations can be helped better operating conditions

Figure 7 – Under high pressure applications, to protect rubber part of expansion joint, please be carreful to flange bolt positions.

Figure 8 – The instalation spacing between pump and compensator must be multiplied with 1 or 1.5. Pump connection points souldnot have extremely loads. Pump must be fixed on the ground.

Advices After Installation

Protect the bellows from welding works area. Donot paint bellow part of the rubber expansion joints. Solvents can damage the bellows. High operating temperature applications can damage bellow parts. Use fixed points and guides acc.to our instrucitons. Tie rods can give a long lasting to rubber expansion joints acc.to applications.