The elastic metal bellowed parts absorbing the heat induced expansion or contraction of pipelines conveying hot or cold fl uids or subject to drastic changes in ambient temperatures are called expansion joints. The most proper and affordable solutions to eliminate those problems are the metal bellow expansion joints designed to compensate different types of size chances, which do not necessitate any maintenance.

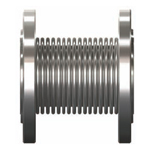

1. AXIAL EXPANSION JOINTS

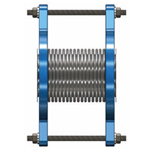

2.LATERAL EXPANSION JOINTS

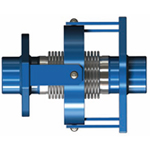

3.ANGULAR EXPANSION JOINTS

|

1. AXIAL EXPANSION JOINTS Axial Expansion Joints are used to absorb the thermal expansion parallel to the axis of the straight pipelines. Long piping systems are divided into shorter expanding sections, and isolated by main anchors. Thus the movements in the individual expanding sections are absorbed by the KRS-14 axial expansion joints in this section. |

|

2.LATERAL EXPANSION JOINTS Lateral Expansion Joints are specific expansion joints, consisting of one or more angular expansion joints used to absorb the thermal expansion in a plane vertical to the axis. The potential expansion amount to be absorbed can be augmented by increasing the distance between the bellows. This type of expansion joints may absorb big amounts of expansions. Especially the assemblies consisting of more than one lateral expansion joints are the most effective ones to absorb big amounts of expansions. |

|

3.ANGULAR EXPANSION JOINTS Angular expansion joints are the specific ones, absorbing the thermal expansion of the pipeline by transforming them to angular movements in a plane vertical to the axis. They may absorb the movements in one or more directions (in a plane vertical to the axis of the pipe). The assemblies consisting of two or more lateral expansion joints may absorb big amounts of expansions. |